Wall Parging for ICF Construction: What It Is, Why It’s Needed, and How to Do It Right

If you’re working with Insulated Concrete Forms (ICFs), one question always comes up: how do you finish that exposed foam between the ground and your siding? The answer is wall parging—a critical step that not only protects your build but also enhances its curb appeal.

We’ll explore what wall parging is, why it’s essential in ICF construction, which materials work best, and how to apply it for lasting results.

What Is Wall Parging?

Wall parging is a thin coat of cementitious material applied over concrete or ICF foam surfaces. Traditionally used to smooth poured concrete walls, parging hides surface flaws and provides a clean, finished look.

In ICF Systems

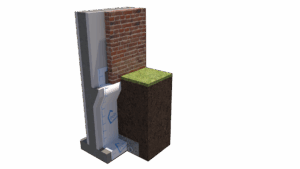

In ICF construction, wall parging refers specifically to a protective and decorative coating applied over exposed foam. This is usually found:

- Between the finished grade and the bottom edge of cladding

- Around exposed portions of basements, frost walls, and foundation perimeters

Parging in ICF applications:

- Shields foam insulation from UV damage, weather, pests, and fire

- Adds aesthetic value to visible areas

- Complies with building code requirements for foam coverage

Why You Need Parging in ICF Construction

According to building codes and our CCRR (Code Compliance Review Reports), all exposed ICF foam must be covered—both inside and out. The only exceptions are for enclosed attics and crawlspaces.

For above-grade exteriors, this means every ICF structure must have a protective layer like parging, stucco, or approved cladding to ensure:

- Fire resistance

- Moisture and UV protection

- Long-term appearance

- Structural integrity

Best Materials for ICF Parging

When choosing a parging material, look for options that are:

- Durable

- Aesthetically pleasing

- Low maintenance

- Code-compliant

Popular ICF Parging Options:

- Stucco & EIFS Systems Great for full wall applications with textured finishes.

- Brick or Stone Veneer A high-end look with excellent durability.

- Corrugated Metal Panels Offers a modern look, but may require replacement due to rust over time.

- Durock B2000 Cementitious Coating A standout option from a Canadian manufacturer (not to be confused with the U.S. Durock brand). It’s a pre-blended skim coat formulated to bond well with ICF and resist weathering.

Installation Tips for Parging ICF Walls

Proper prep and execution ensure your parging layer performs over time. Here’s a typical workflow:

- Clean and Rasp the Surface: Ensure the foam is free of dust, debris, or moisture.

- Apply Base Coat: Use a cement-based or acrylic-modified parging compound. (swapped these 2 processes)

- Install Reinforcement” Mesh or Lath Essential to prevent cracking in cementitious parging materials.

- Apply Top Coat: After mesh is installed and base coat has dried, apply the finish coat to conceal the mesh.

- Add Finish Texture or Paint: Optional but ideal for improving curb appeal and color coordination.

- Ensure Proper Lap Over Waterproofing Membranes: Create a seamless transition from below-grade waterproofing to above-grade parging.

Wall parging isn’t just a visual upgrade—it’s a building science necessity in ICF construction. The right parging material protects your investment, enhances your exterior, and ensures code compliance.

If you’re sourcing ICF-friendly wall finishes, consider cementitious coatings like Durock B2000 or systems that are designed to adhere to foam and handle the elements.